Diligence Offshore Services, LLC is developing an Offshore Wind Energy Innovative Supply Chain Support System (OWEISCSS). As part of this overall system being built on the Texas-Louisiana Gulf Coast by an African American group of professionals, an Innovative Energy Efficient End-Use Vessel Facility is being developed to help achieve many of the future renewable offshore wind energy wind farm goals mandated by the Biden Administration. The operation sits on a 125+ acre site strategically located in close proximity to our deep-water integration site and monopile manufacturing facility. The facility is expected to be operational in first quarter 2027.

As an Offshore Wind Innovative Energy Efficient End-Use Vessel Facility , we will effectively provide the following critical support scope of work:

The monopile foundation manufacturing facility will be built on a 150 acre tract of land in very close proximity to both the Innovative Energy Efficient End-Use Vessel facility, and the Offshore Wind Integration facility.

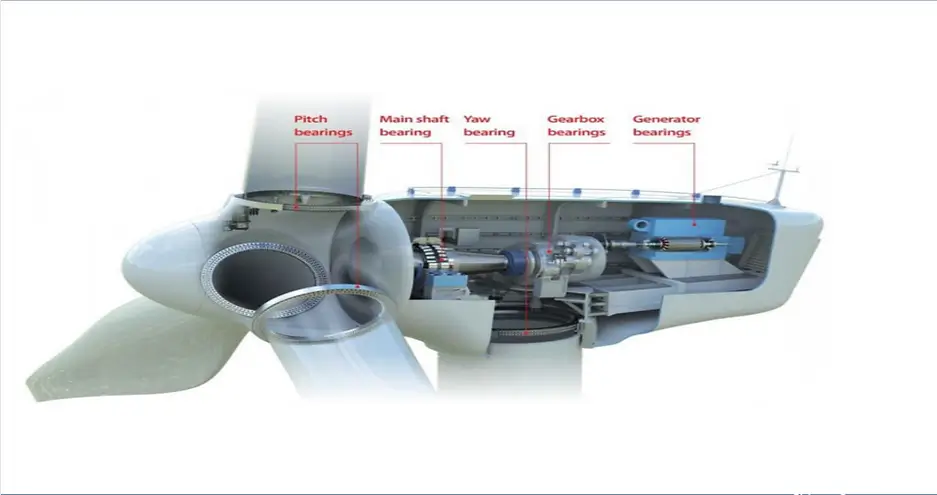

Modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus aerodynamic performance and load control. Yaw bearings are used for angular realignment of the nacelle into the predominant wind direction. These applications require long periods in nearly stationary positions with large stochastic loads. Due to this demanding load environment and the fact that bearings exist in the critical load path, their design becomes critical to the safety and reliability of most turbine designs. On-site manufacturing will be carried out on a 100 acre site at the Port.

© 2023 by Diligence Offshore Services LLC